The project below introduced me to Remo.tv where I have been happily playing a claw machine over the internet for too long (I never did win the Pikachu…). There’s a lot of power and possibilities here and the use of DeepAI models over the web is just as cool, well worth a look.

LED Jewellery

I found this cool Instructable for making LED jewellery out of brass rod and wanted to make something for my son’s birthday, he likes foxes! I found the LEDs were just too bright without any resistors so I managed to incorporate some tiny 0204s into the design. It seems strong enough, but time will tell, and I think if I had put the battery in the other way it would have not shorted if you pushed it in too much, but I am not re-soldering those LEDs the other way now!! It’s super fiddly, but using a bit of solder paste helped to get things in position and the solder to stick. I need to get a badge back on there somehow too…

Nerf gun turret

I was working on a Nerf gun turret in my previous employment at a special needs school but never had time to finish it. There are a lot of very disabled children who don’t get to run around and wrestle like other kids do so I was trying to think of a way of them getting in on the ‘boisterous play’. The Nerf gun turret was meant to be something they could use with a small thumb joystick similar to one used to drive an electric wheelchair, or even controlled with eye gaze tracking. For this iteration I just hooked it up to a USB gamer joystick.

There are definitely some improvements to be made, the rig is flimsy, the tilt servo could do with some gearing, the gun often jams and I may have smoothed the input a little too much, but we are getting there! I’d love to hook it up to the Husky Lens and get some AI image tracking going on… face recognition to only attack a certain person?

Raspberry Pi Portable Power & Safe Shutdown

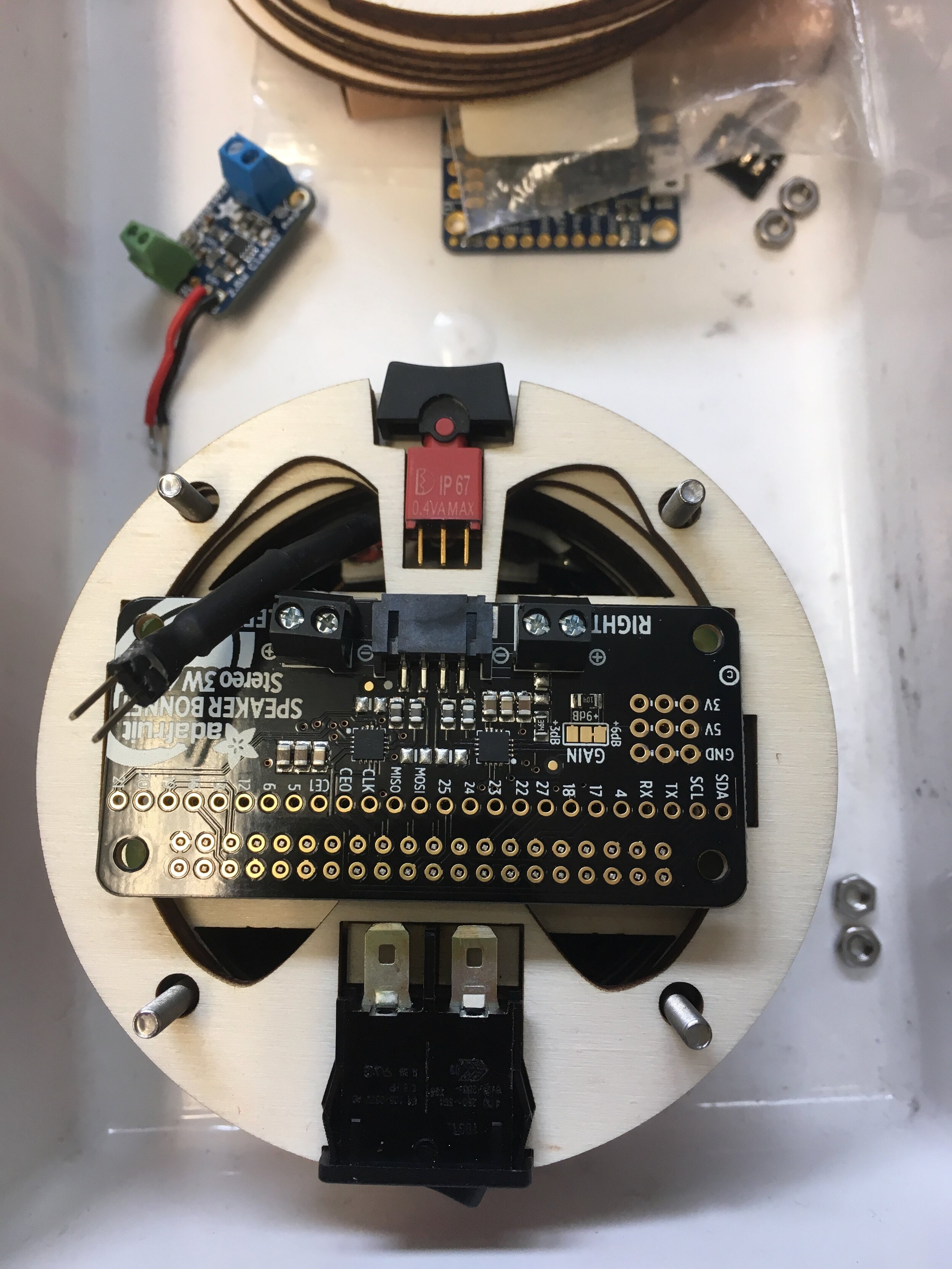

So I have been building a few portable things with Raspberry Pi Zero lately and I’ve been using the Adafruit PowerBoost board. Its a great board for bumping a 3.7V LiPo battery output up to 5.2V for running Raspberry Pi projects, plus it handles charging, has low battery detection and you can turn off the output with a pin. The only problem was being able to do a safe shutdown and then use a pin from the Pi to cut the power. I’m kind of surprised there isn’t a board and prebuilt solution for this and it took a lot of research before I came across NeonHorizons LipoPi repository. The functionality I was after was in the Power Up/ Power Down version and I used the ‘Simple Press’ section as the basis of my circuit. I was using the Adafruit Speaker Bonnet for my project so I could not use the suggested pin 18 and changed it to 27, but the rest stayed the same. Anyway, I put the suggested circuit onto some strip board and the solution worked perfectly so kudos and thanks to Daniel Bull. Check out the repo for the code, instructions and circuit diagrams, my circuit is below.

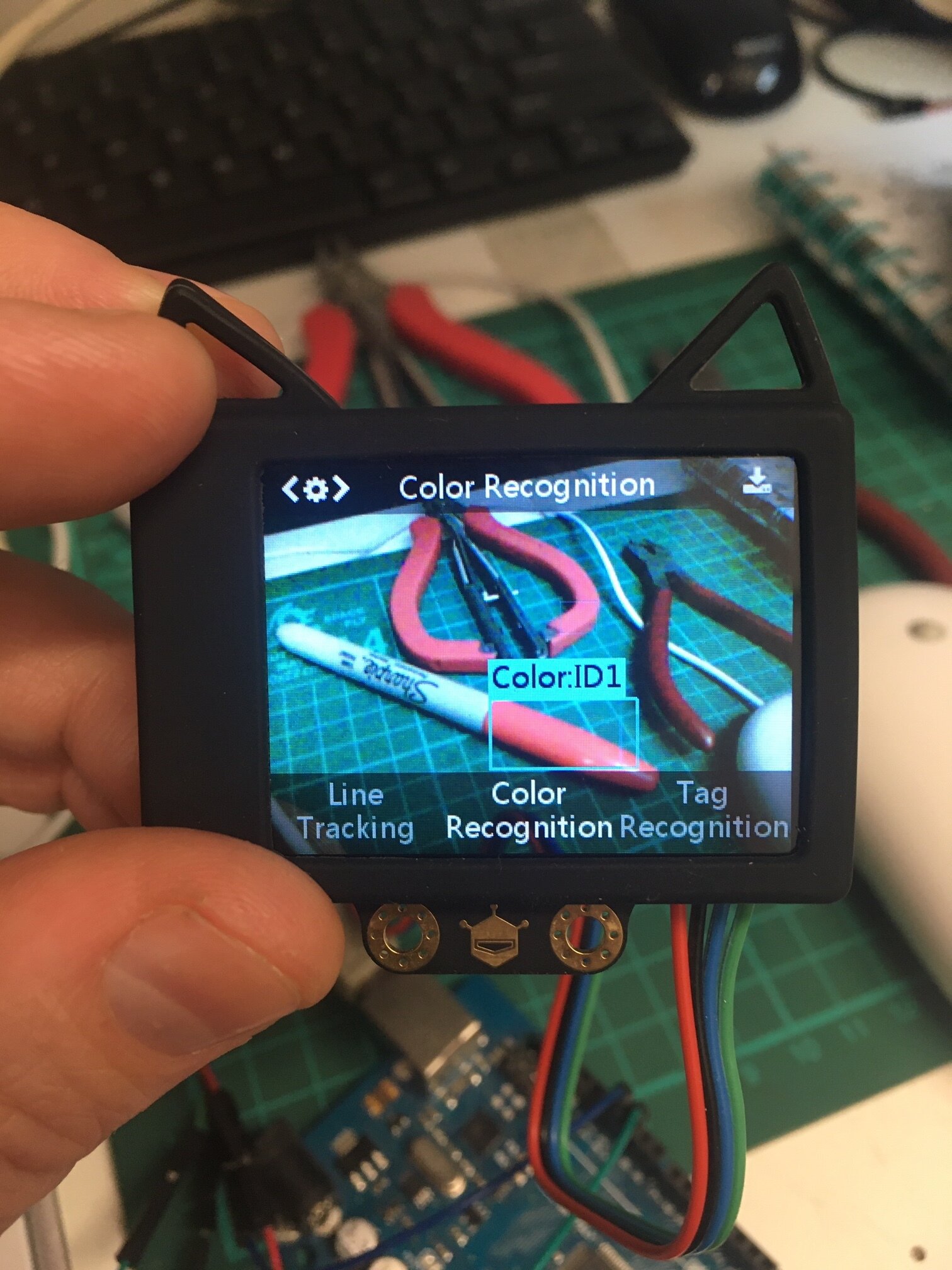

Huskylens Easy-to-use AI Vision Sensor

I just received my DFRobot Huskylens having funded the Kickstarter a while back. Of course there is zero documentation at the moment, I couldn’t find anything much online and was having trouble reading serial from the device. In the end I searched on Github and found an Arduino library. If you download the zip, unzip it and then rezip the ‘HUSKYLENS’ folder inside the main folder then you can import it as a zip library as described here and then access the examples.

I had a quick play with the device and managed to get location data coming in to my Arduino for tracked objects and it seems pretty simple to learn new ones. Now if I can hook up some face detection to the nerf gun turret I am building we can have some fun…

SpotiPi

I’ve been getting friendly with the Raspberry Pi Zero for audio applications and I discovered some great new boards just before Christmas by Pimoroni that include a DAC, a screen and some buttons. My son loves his music but is at that age that if you give him a device to play Spotify on he will just fiddle with the device so I wanted to give him a Spotify player without the distractions and something he can have a little party with his friends. I came up with this little boom box in gold and black that displays the album art and gives you volume control, play, pause and skip buttons, is USB rechargeable has great sound quality, is pretty loud and has a long battery life. I can select a playlist on my phone and then he can take it away. Also clear front panel so he can check out all the circuitry and room for adding some more buttons and faders!

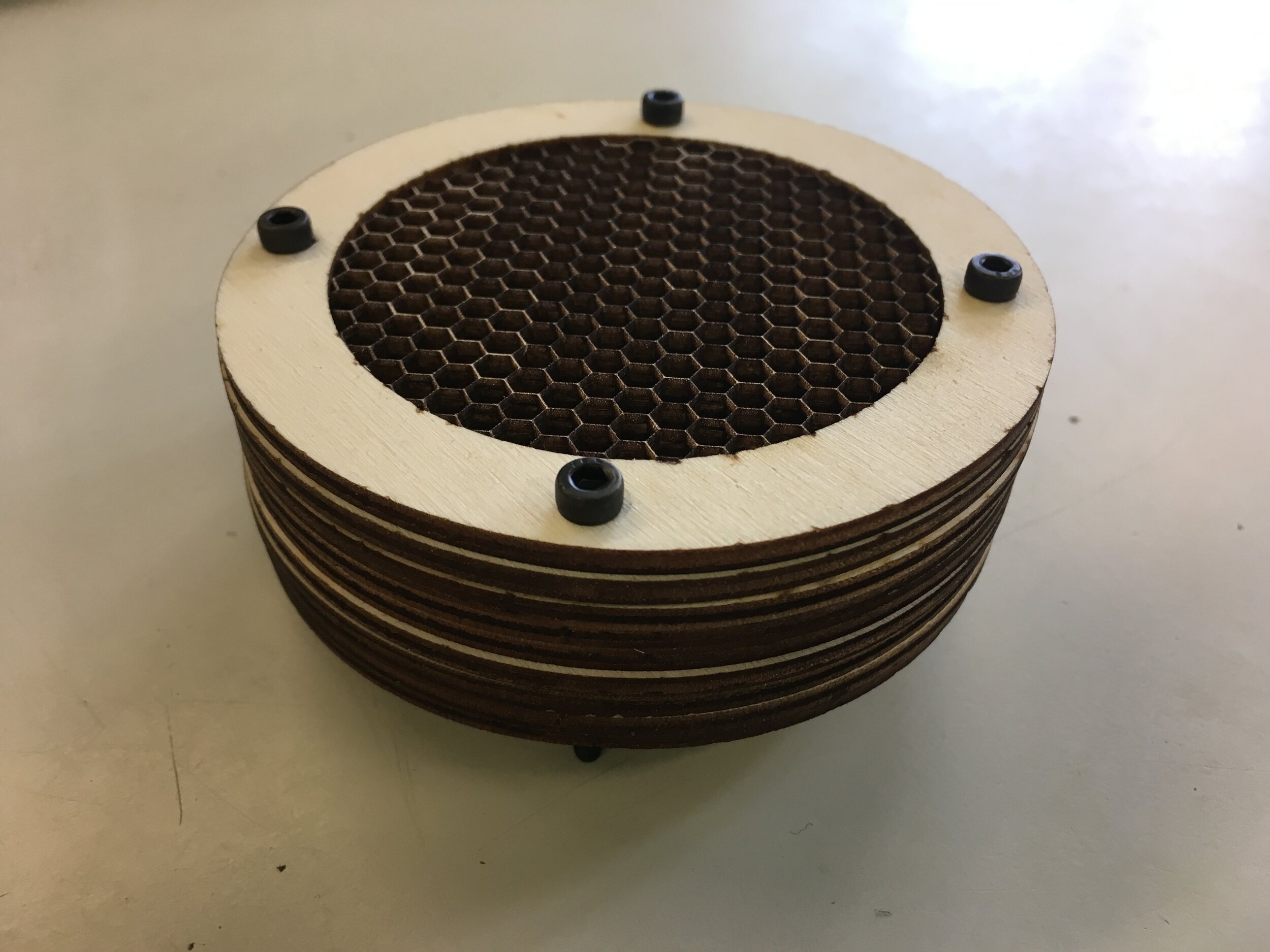

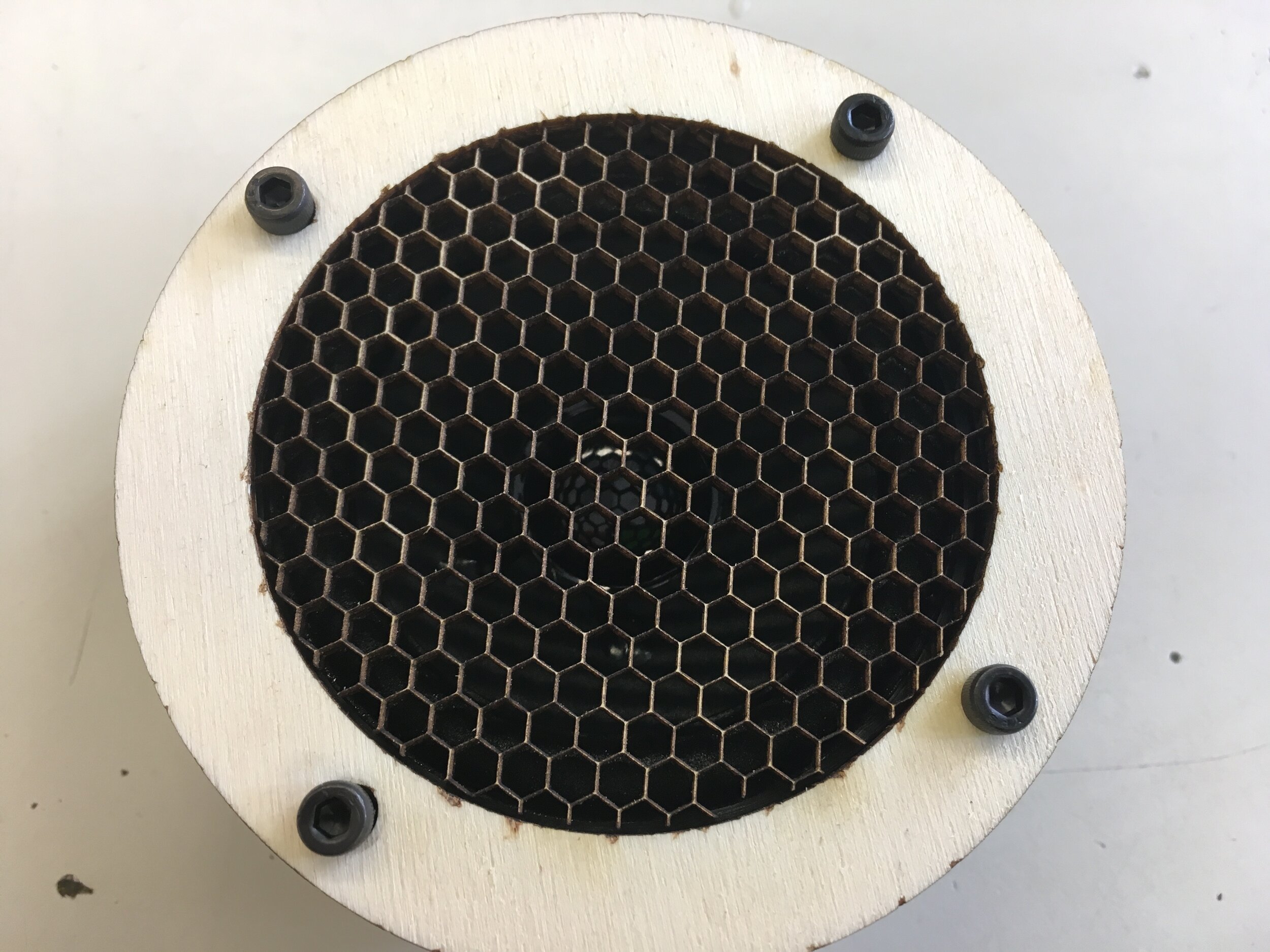

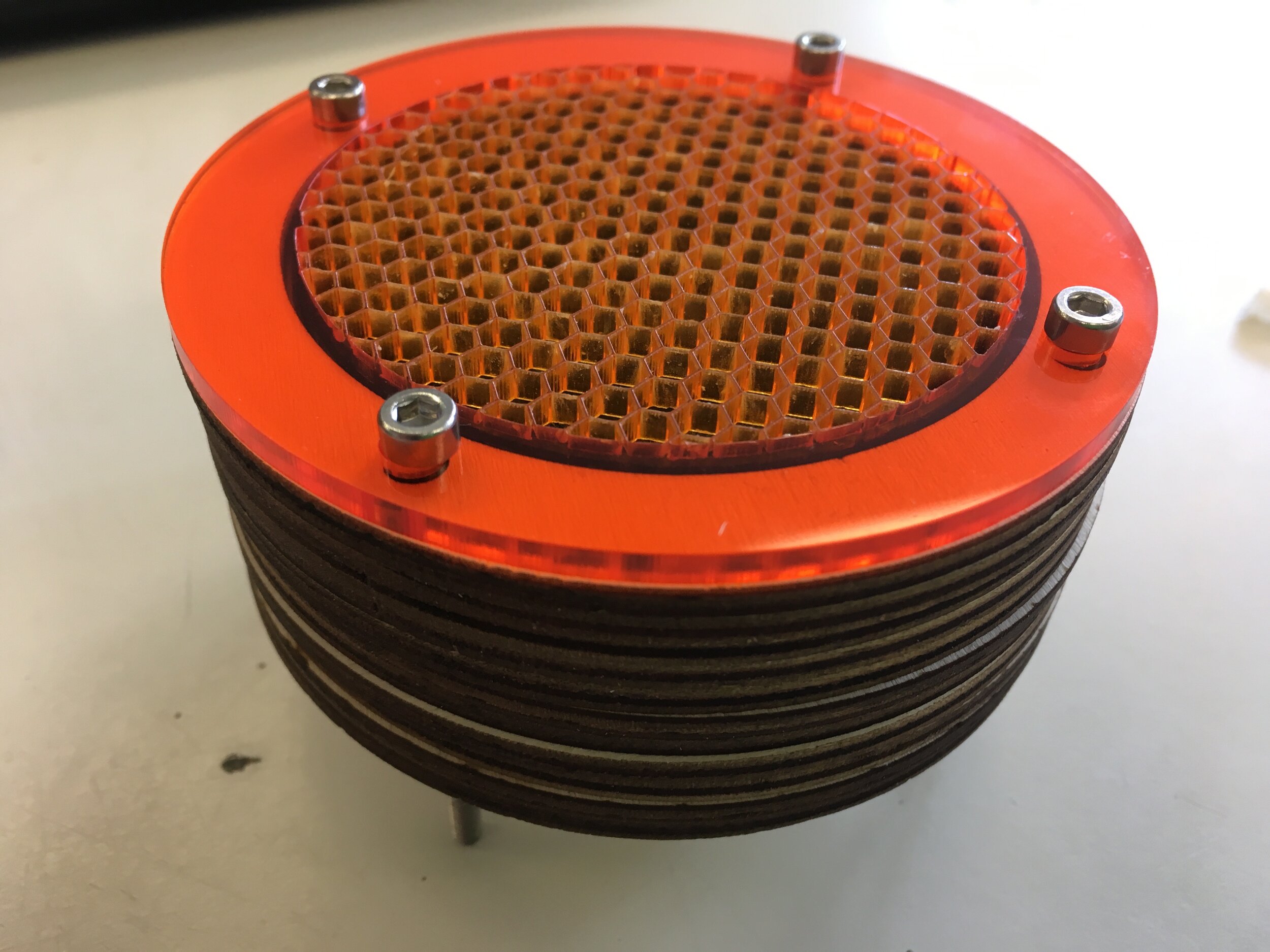

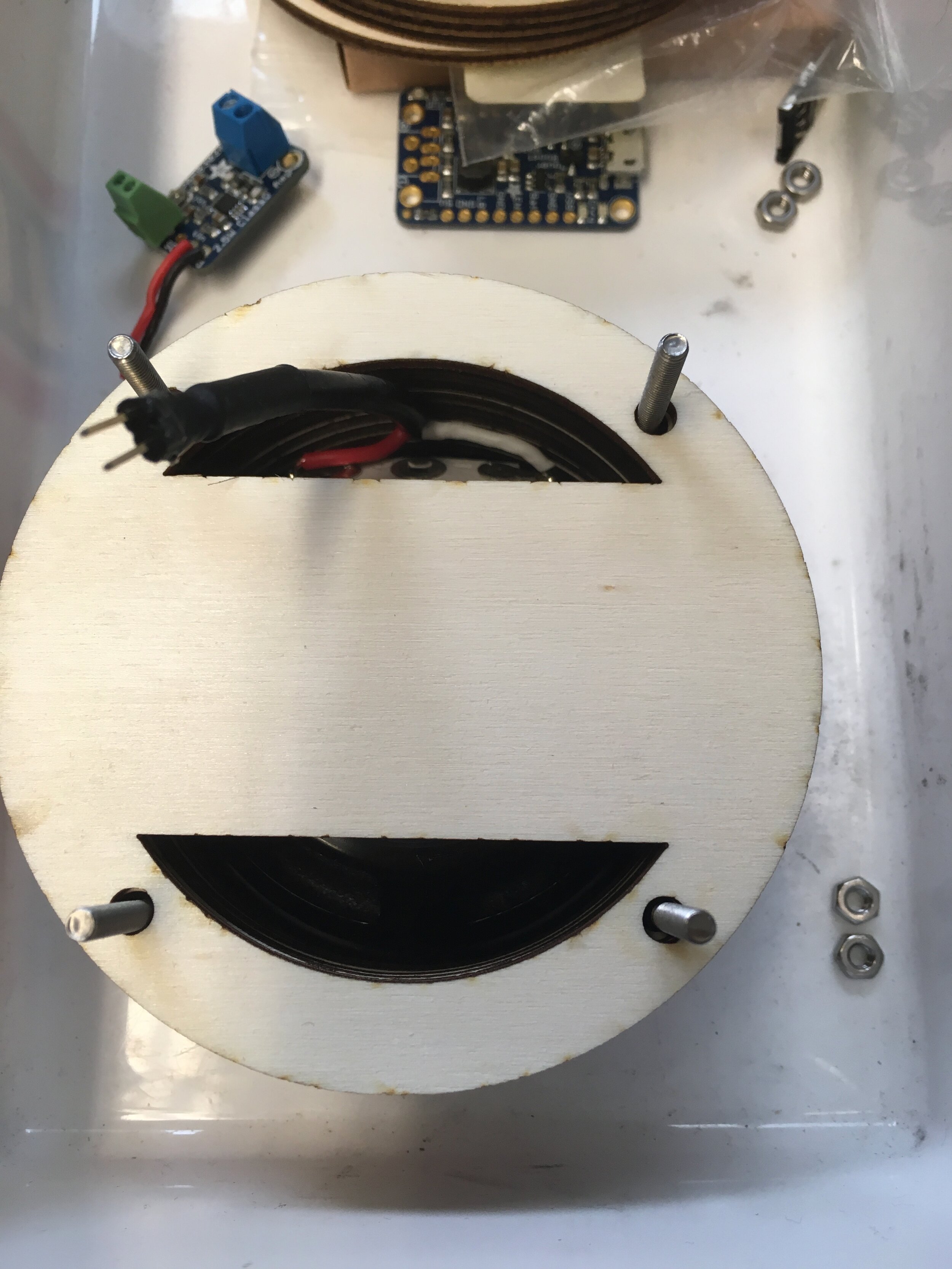

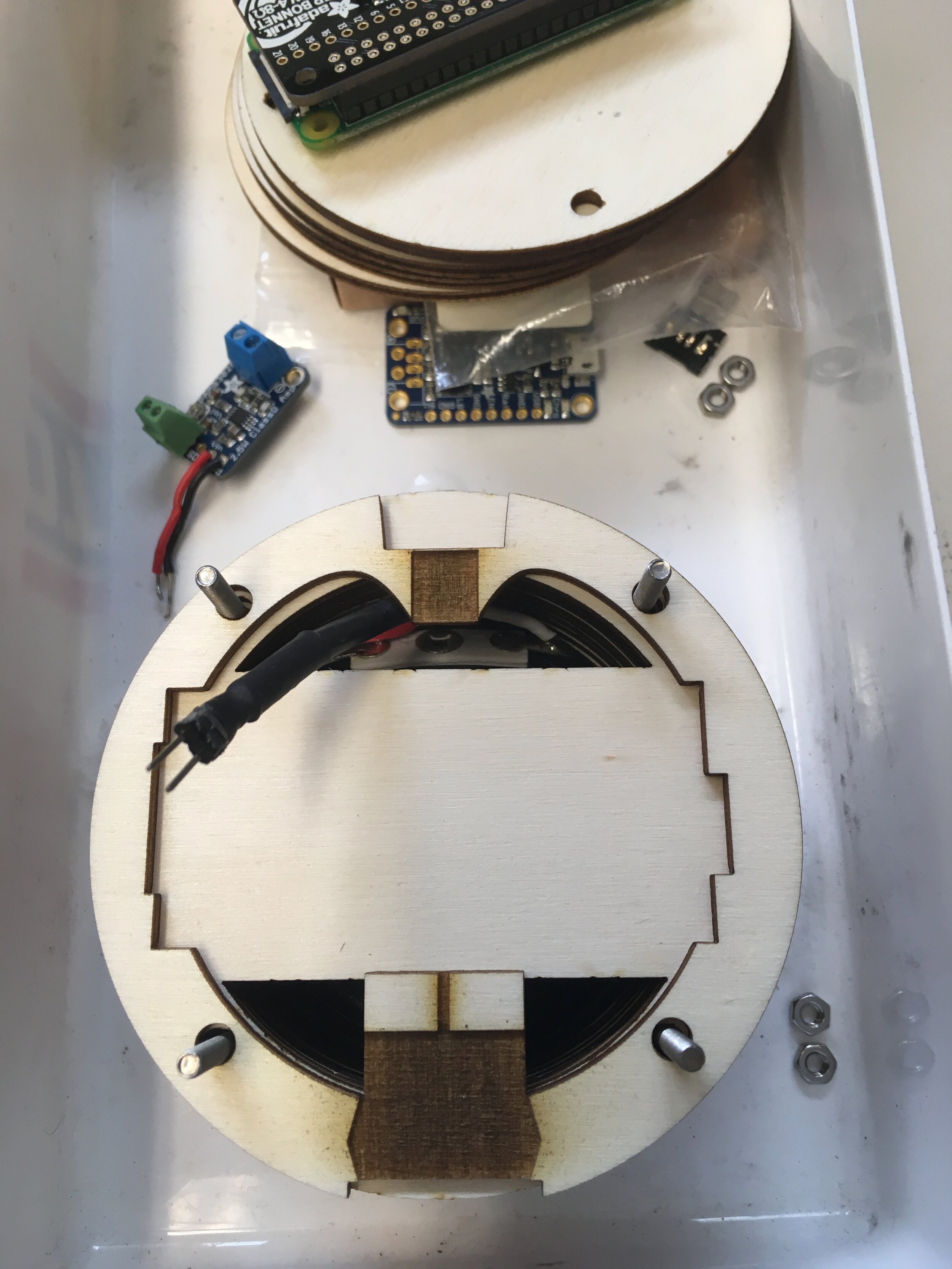

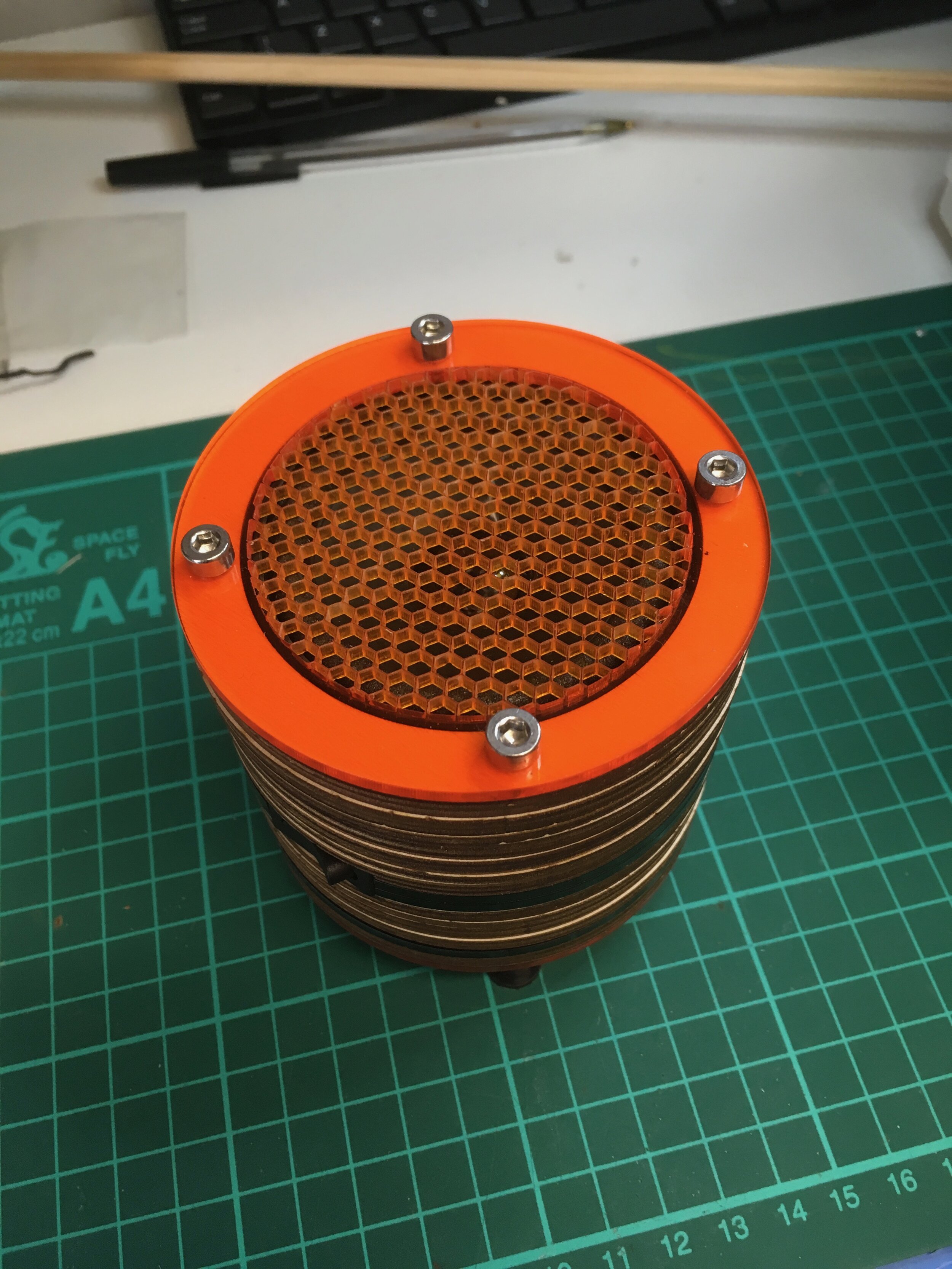

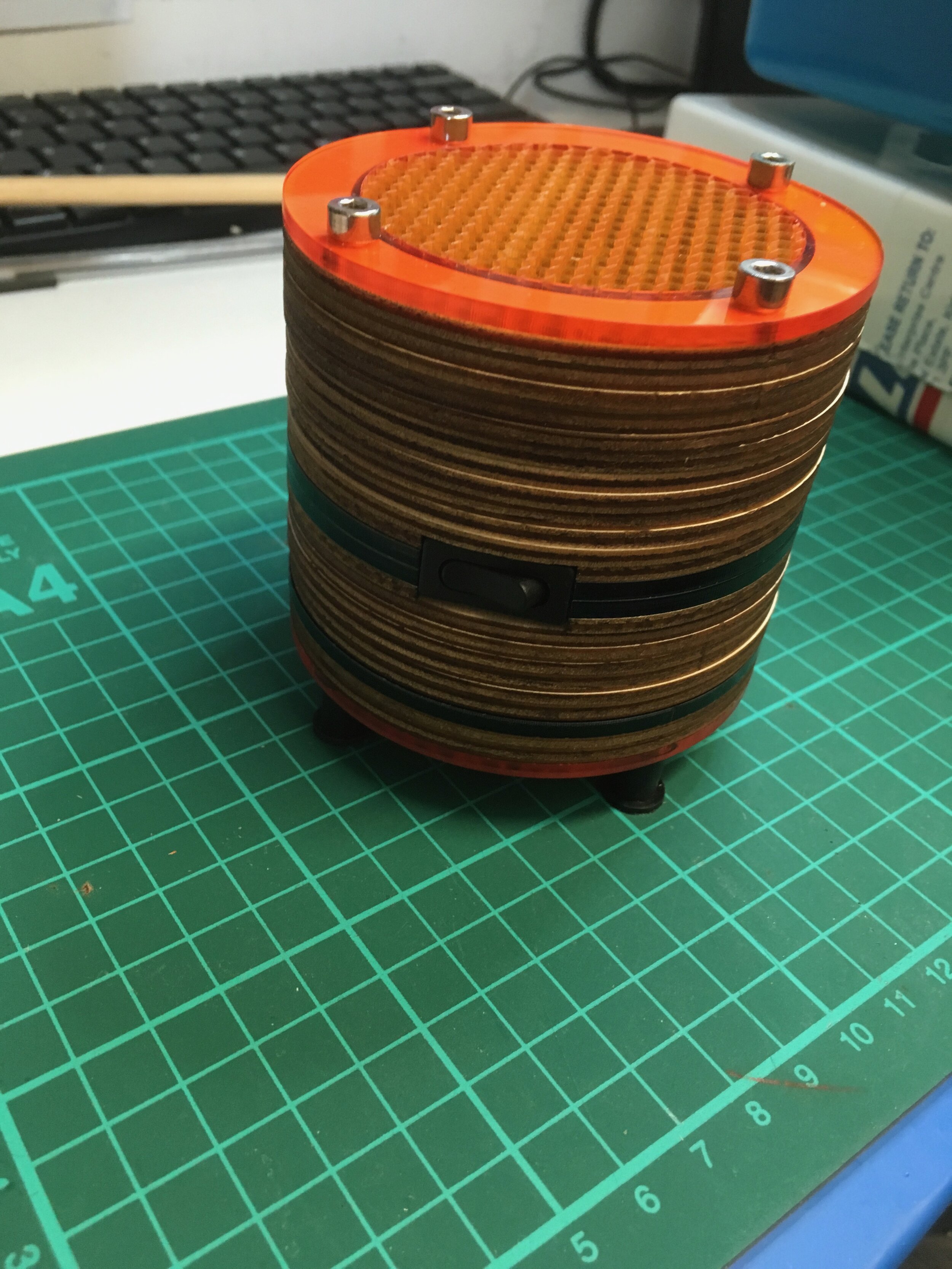

Sound Fragments

I have been working on some Raspberry Pi powered speakers for a while now. These devices owe a lot to the interactive bird sculptures that I made for Forest of Imagination in 2018. The devices have a decent speaker and amplifier, battery, are USB chargeable with exposed volume controls and can communicate with one another. Right now I am running PD on them to generate sounds and hope to add functionality for other inputs and outputs such as sensors, microphone and LEDs. The idea really was to be able to create a network of smart devices capable of producing decent quality sound for sonic art installations.

Eventually I hope to make this project open source and share the code, designs and bill of materials on line.

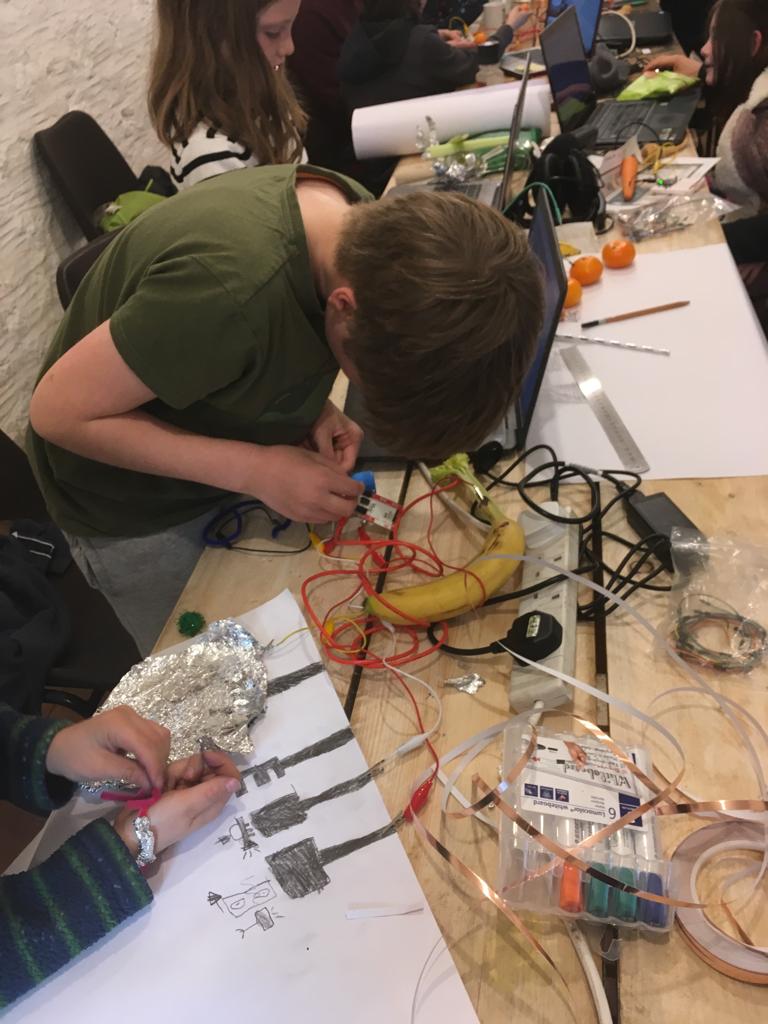

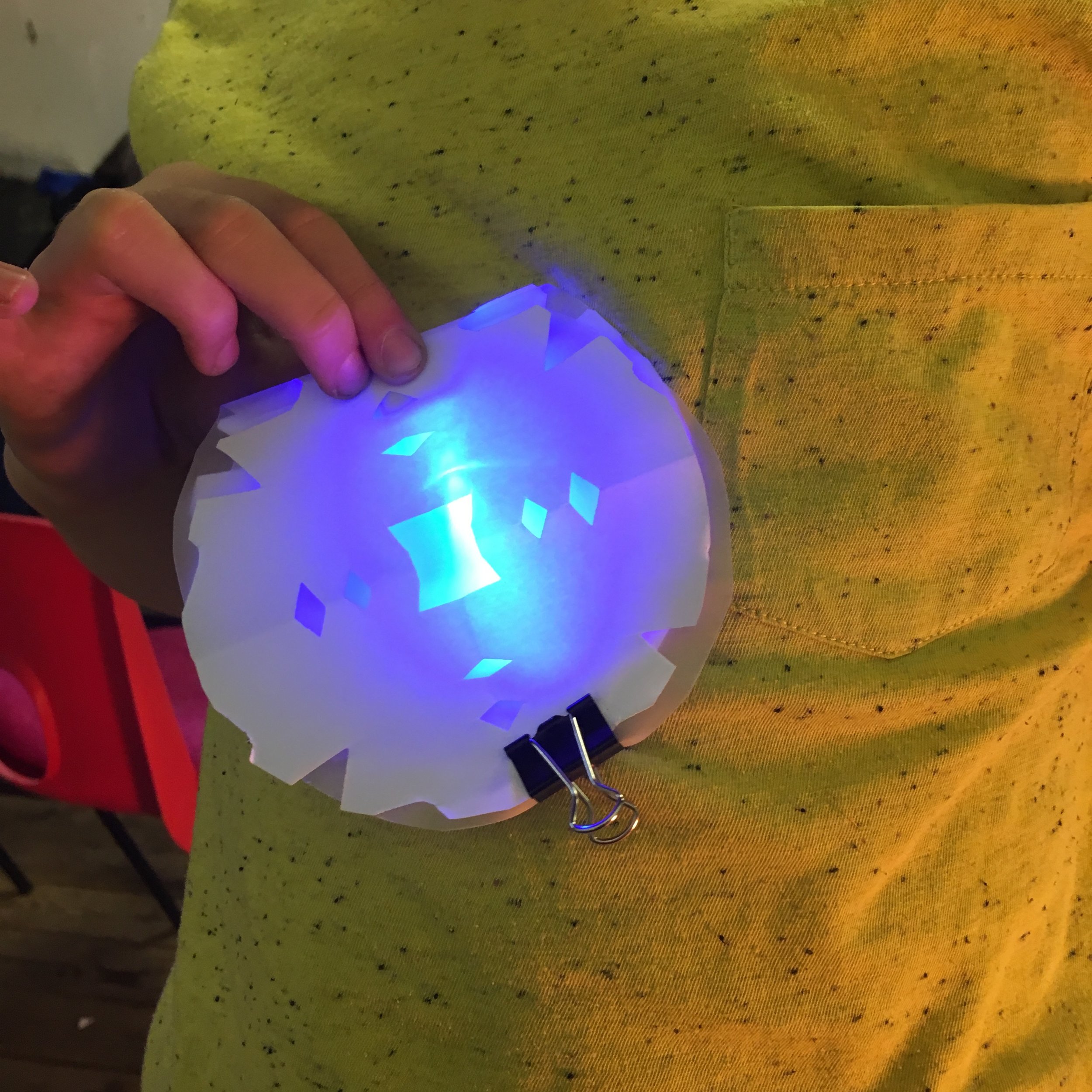

STEM / STEAM workshops

I recently did some STEAM (Science Technology Engineering Art Maths) workshops at Edventure in Frome. We explored paper circuits, programming in Scratch and making interfaces using the Makey Makey. I had lots of fun and the feedback was great, there were some impressive creations!

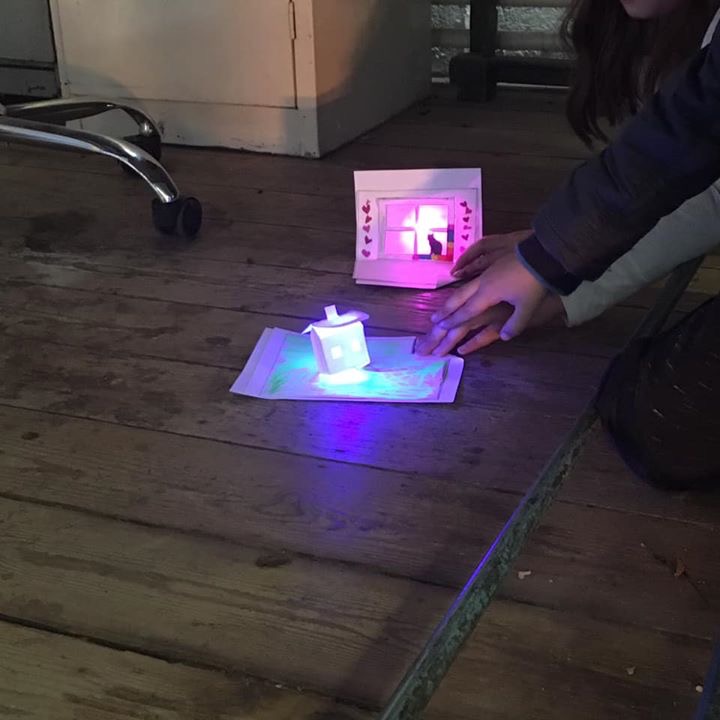

Miniature World Illuminations - Installation Prototype

I have been designing an install for the Bath based Forest of Imagination event in the summer of 2019, I built this prototype to test out some of my ideas and it was great fun. I can’t wait to build some more of these!

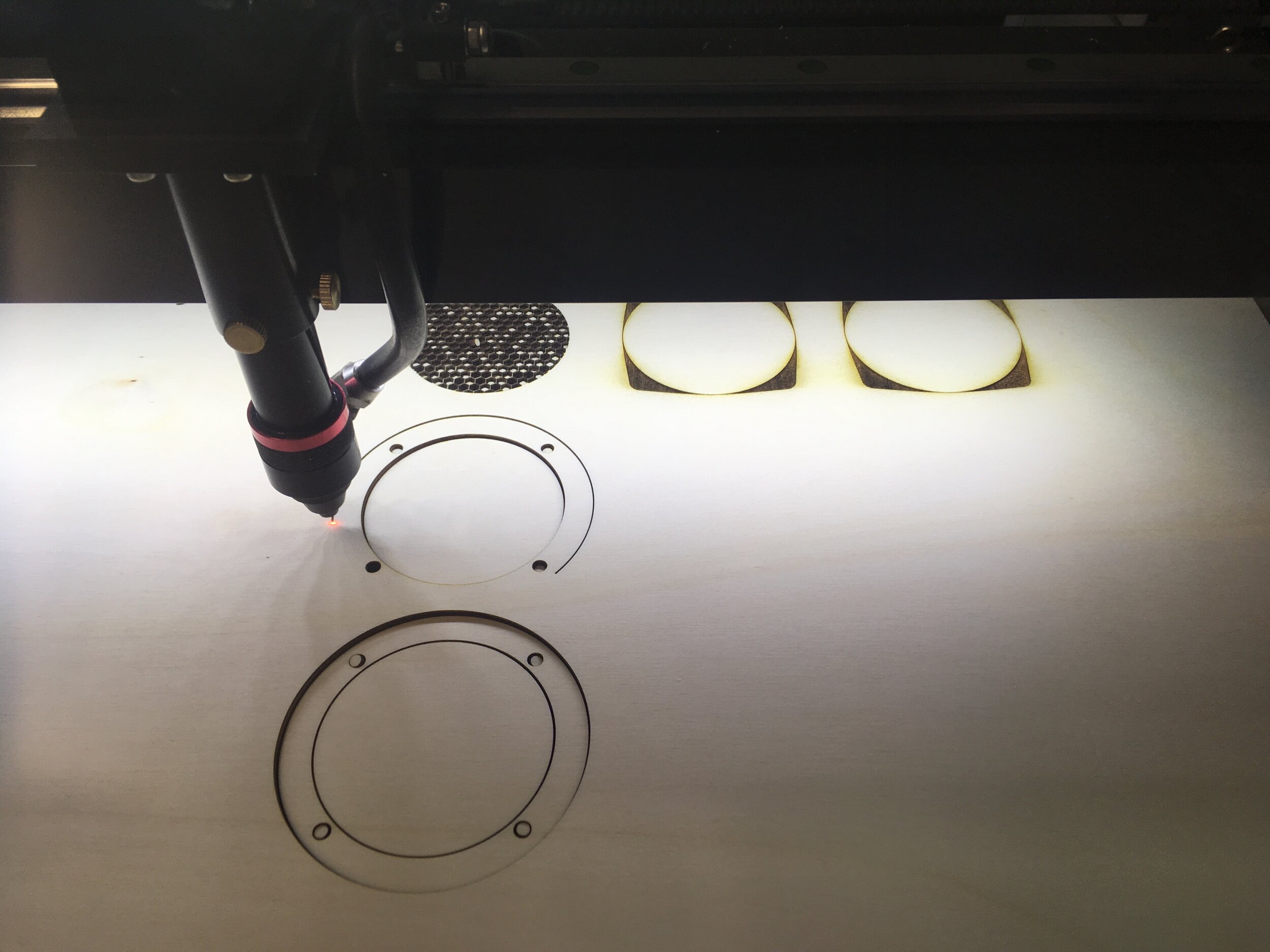

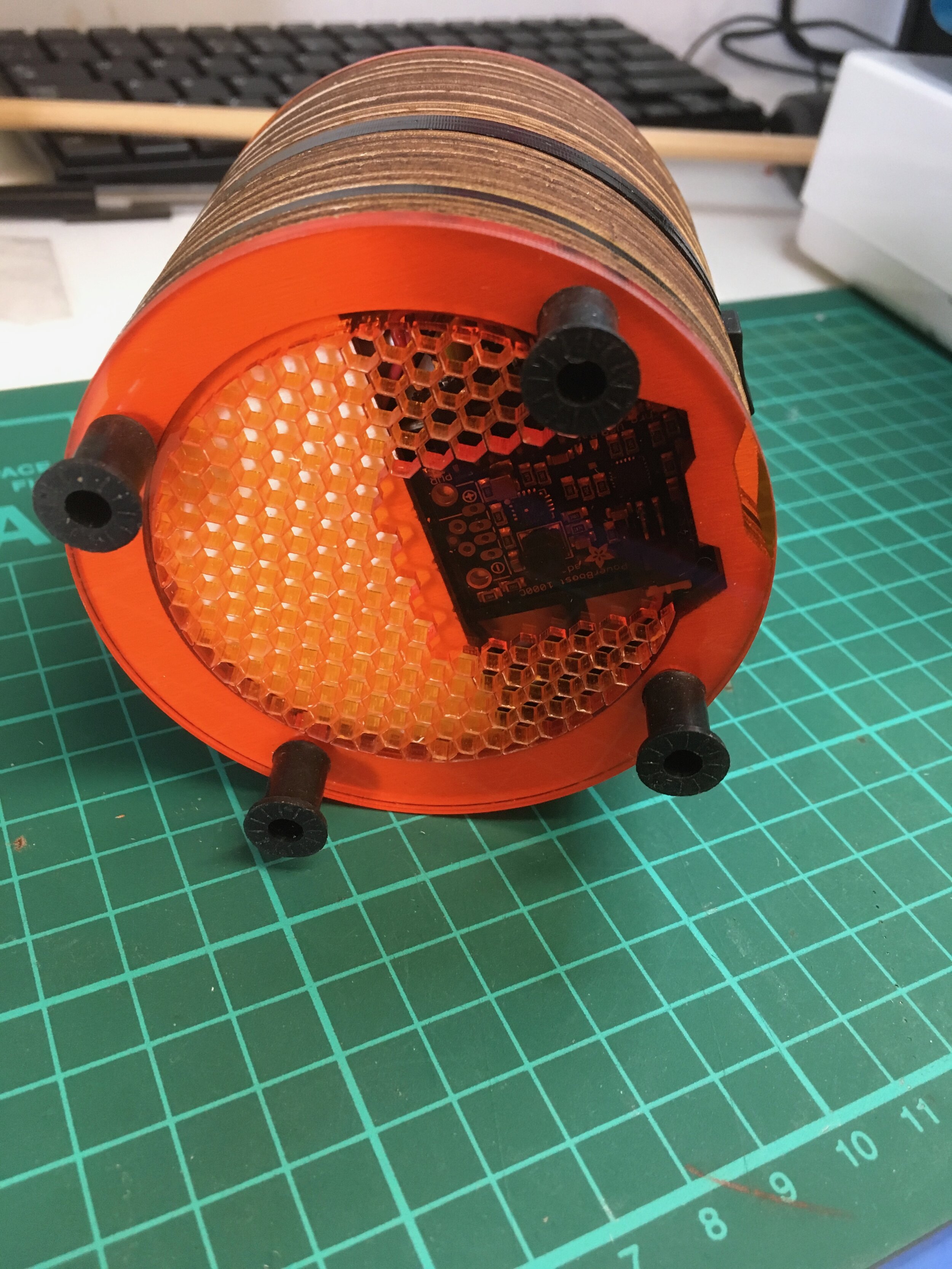

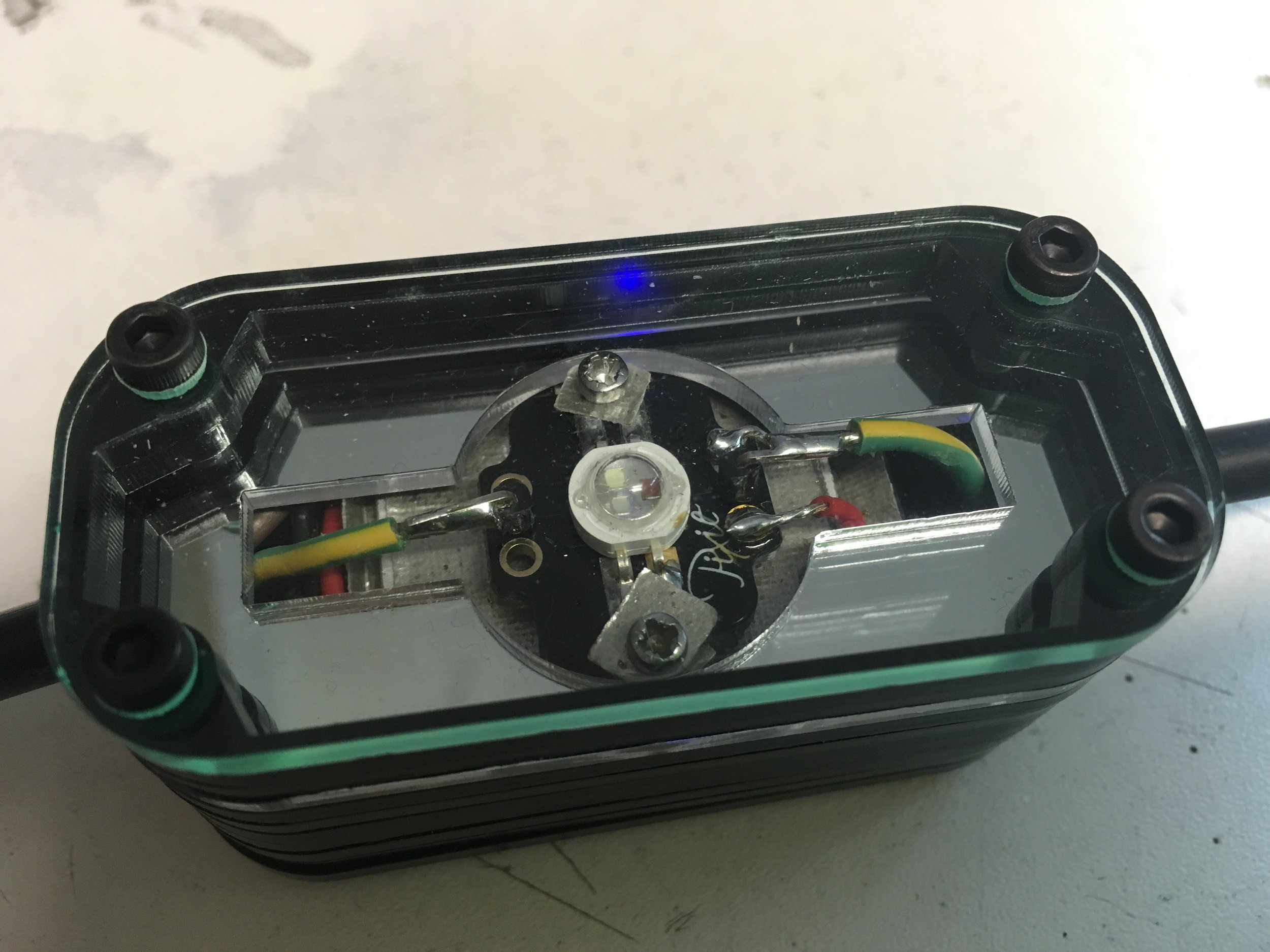

Custom Lasercut Cases for Power LED Modules

It was about time to make a nice case for my custom LED modules!

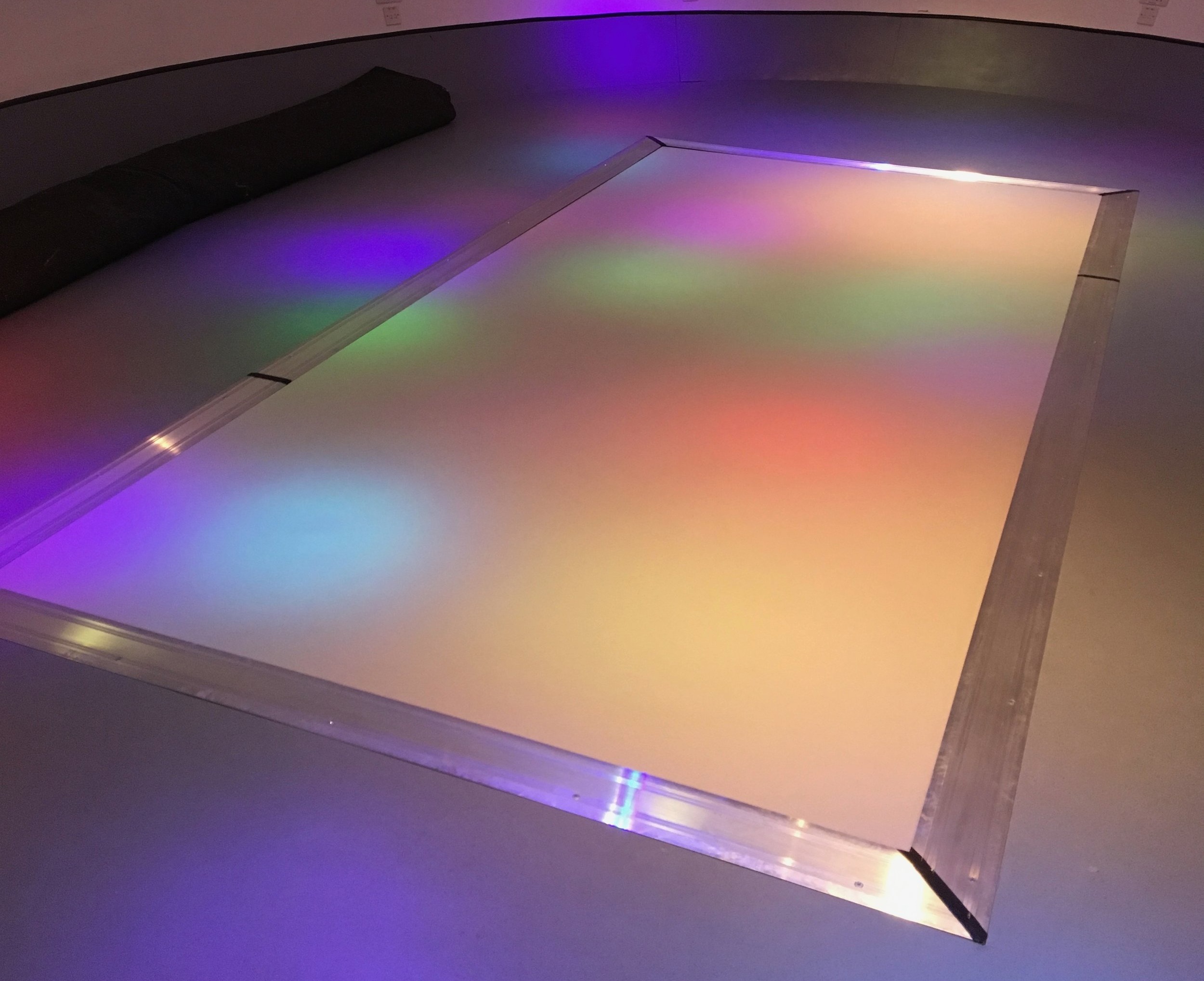

Smart Film

Well, the Shutter Glass was super cool, but I can’t seem to find it in big pieces and you need to use power to hold it dark . Smart Film is frosted and then you apply power to clear it which is more what I am after, again, cool stuff!

Shutter Glass

Been playing with some shutter glass for an upcoming project, really cool stuff!

The Vibrating Floor

Pretty much since I started working at Three Ways School, nearly ten years ago now, I have had my eye on a cavity which was built into the Sensory Studio floor. It was pretty much sealed in and over the years I have done investigations and tried to get hold of missing plans etc to find out what is down there. Over the last couple of years I started work in earnest and got some budget to create a vibrating floor.

Having come up with a rough design I set about trying to find a carpenter willing to take on the project. Once I had detailed my requirements, mostly I found that the carpenters stopped returning my emails and answering my calls. However, Andy Emmerson (Emmerson of Bath) was made of sterner stuff and agreed to take on the build.

We built a floating floor mounted on rubber supports and powered by two powerful shaker motors. These motors can be driven with low frequency audio meaning you can feel music with very limited audible sound. Andy did a great job on the frame, there are no rattles and the floor moves freely for a great responsive and very powerful vibration.

I am currently working on a suite of tools for using vibration effects with SEN children and will eventually link the visual floor projection with the underlying vibration events.

Puzzles for the visually impaired

It may have been a little quiet around the blog lately, in part due to the fact that I now have access to a laser cutter and have been lasering everything I can get my hands on.

A teacher at Three Ways School was asking about simple puzzles of limited pieces and it got me thinking about puzzles for the visually impaired. After a simple prototype I made an 8 piece puzzle with a raised pattern on one side and each tab being a different shape. I ran off 5 of them which are out with classes being tested right now.

Feather Huzzah32 - ESP32 OSC

I was a fan of the old Huzzah board based on the ESP8266 chip, but it only had one analog input which made it unsuitable for some projects. The new ESP32 chip has loads of analog inputs, bluetooth/BLE and is pretty packed with GPIO and features! Check it out here at Adafruit.

I have been using it to send button and fader/sensor readings over WiFi using OSC to my computer running Max MSP, it is a great tool. I have created a repository here with all the coding and information to set it up.

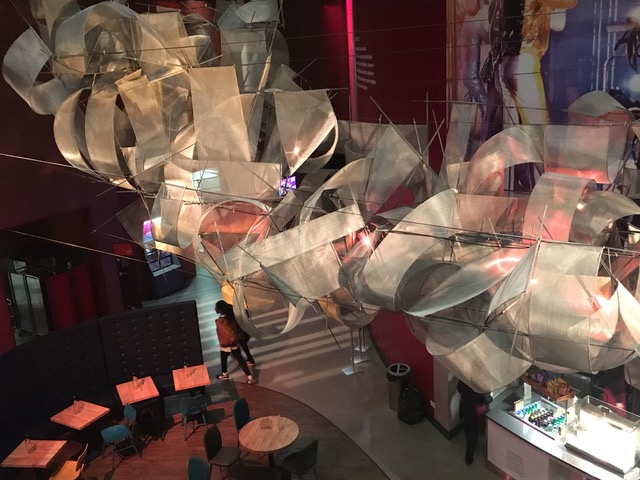

Esther Rolinson 'Revolve' installation at Curve Theatre, Leicester

So, this is the installation for which I have been working so hard on the modular power LED string. See those glowing internal lights?

Beautiful work, just sad I didn't get to see the finished piece in person.

Modular Power LED string

Finally there, 28x 3W LEDs in a modular design with around 70 metres of cable. Off to deliver to Esther Rolinson for her installation at The Curve Theatre in Leicester.

Hello world!

It lives! 15 more to make.

Assembly line up and running...

With a little child labour assistance...

Modular Power LED strip

One down, 24 to go...